Facility Layout & Piping Engineering

At Nugos Engineering Pvt. Ltd., we specialize in delivering intelligent facility layout and piping engineering solutions that enhance operational efficiency, safety, and maintainability. From concept to construction, our designs are developed to align with technical, regulatory, and business objectives.

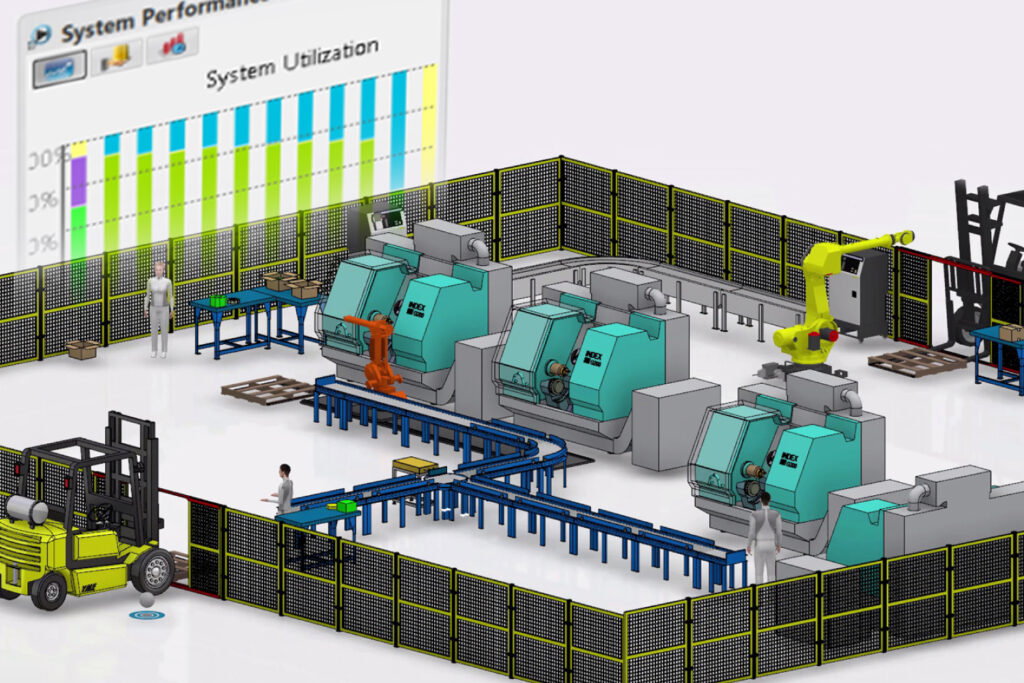

Facility Layout Engineering

Our services include:

2D and 3D facility layout design

Creating detailed 2D and 3D facility layouts to optimize space utilization, workflow, and equipment placement for efficient operations.

Equipment placement and accessibility planning

Strategically planning equipment placement and ensuring easy accessibility for smooth operations, maintenance, and safety compliance.

Plot plan development

Designing comprehensive plot plans to optimize land use, infrastructure layout, and ensure compliance with zoning and regulatory requirements.

Utility and service area zoning

Designing efficient zoning for utility and service areas to ensure optimal functionality, easy access, and compliance with safety standards.

Integration of safety and maintenance considerations

Incorporating safety protocols and maintenance-friendly designs to ensure long-term operational efficiency and worker safety.

Compliance with ergonomic and regulatory standards

Piping Engineering

Our piping engineering team ensures the efficient and safe transport of fluids within industrial facilities through robust, code-compliant piping systems.

Services include:

Piping design and layout (3D modeling in PDMS, SP3D, AutoCAD Plant 3D)

Developing precise piping designs and 3D layouts using PDMS, SP3D, and AutoCAD Plant 3D to ensure efficient, clash-free system integration.

Preparation of piping isometrics and GA drawings

Creating detailed piping isometrics and general arrangement (GA) drawings for accurate fabrication, installation, and project documentation.

Pipe stress analysis (using CAESAR II or equivalent tools)

Performing comprehensive pipe stress analysis using CAESAR II or equivalent tools to ensure system reliability under thermal, pressure, and dynamic loads.

Material specification and BOQ preparation

Defining precise material specifications and preparing detailed Bills of Quantities (BOQs) for accurate procurement and cost estimation.

Support design and flexibility analysis

Designing pipe supports and conducting flexibility analysis to ensure structural integrity and accommodate thermal movements and loads.

Piping routing for critical and non-critical systems

Planning efficient piping routes for both critical and non-critical systems to ensure safety, functionality, and ease of maintenance.